If you’re looking for the best clamps for cutting boards, you’ve come to the right place. In this article, we’ll discuss the different types of clamps available and which ones are best suited for cutting boards. We’ll also provide a few tips on how to use these clamps effectively.

If you’re looking for the best clamps for cutting boards, you’ve come to the right place. In this blog post, we’ll discuss the different types of clamps available and which ones are best suited for cutting boards.

There are two main types of clamps: bar clamps and C-clamps.

Bar clamps are typically used for larger projects, while C-clamps are better suited for smaller projects.

When it comes to cutting boards, C-clamps are the way to go. They’re small and lightweight, making them easy to maneuver around your cutting board.

Plus, they have a tight grip that will keep your board in place while you’re working.

Here are a few of our favorite C-clamps for cutting boards:

1. The Mini Clamp from Rockler Woodworking and Hardware is perfect for smaller cutting boards.

It has a strong grip and is easy to use.

2. The Kreg KHC3S 3″ Screw Clamp is another great option for small projects. It’s made from durable materials and has a comfortable grip.

3. The Bessey BPC-H12 12″ Heavy Duty Clamp is a great choice for larger projects. It’s made from heavy-duty steel and can handle even the most strenuous jobs.

Best Clamps for Making a DIY Cutting Board

How Do You Clamp a Cutting Board?

When it comes to clamping a cutting board, there are a few things you need to take into consideration. The first is the size of the board. You’ll need to make sure that the clamps you use are big enough to grip the board securely, but not so big that they’re difficult to maneuver.

The second thing to think about is the type of clamp. There are two main types of clamps – C-clamps and F-clamps. C-clamps are generally more expensive, but they’re also more versatile.

F-clamps are typically used for smaller projects.

Once you’ve selected the right size and type of clamp, it’s time to get started. To begin,Place the cutting board on a flat surface.

If you’re using a C-clamp, position it so that the jaws are facing up. If you’re using an F-clamp, position it so that the handle is facing up.

Next, open up the jaws of the clamp and place them aroundthe perimeter ofthe cutting board .

Make sure thatthe jaws are evenly spaced and that they’re grippingthe board firmly but not too tightly.

Now it’s time to tighten the clamp. For a C-clamp, simply turnthe knob clockwise until it’s tight enough .

For an F-Clamp , squeezethe handles together until they lock in place .

You may needto experiment with different degreesof tightnessto find what works best for you – too looseand yourboard will be unstable;too tightand it will be difficultto move or cut on .

Finally , once yourboardis clamped down ,you’re readytocut !

Which Clamps are Best for Woodworking?

There are many different types of clamps available on the market today, each with their own unique set of benefits and drawbacks. When it comes to choosing the best clamp for woodworking, the most important factor to consider is what type of project you will be working on. For instance, if you are simply gluing two pieces of wood together, then a small hand-screw clamp would suffice.

However, if you are working on a more complex project that requires multiple clamps, then you might want to opt for something like a bar clamp or pipe clamp. Below is a brief overview of some of the most popular types of clamps used in woodworking:

Hand-Screw Clamp: These are perhaps the simplest and most common type of clamp used in woodworking.

They consist of two jaws connected by a screw mechanism, which can be tightened or loosened as needed. Hand-screw clamps are great for small projects where only light pressure is required, but they can be difficult to use on larger pieces of wood.

Bar Clamp: Bar clamps are similar to hand-screw clamps in that they have two jaws connected by a screw mechanism.

However, instead of being operated by hand, bar clamps have handles that can be tightened or loosened using a wrench. This makes them much easier to use than hand-screw clamps, especially on larger projects. Additionally, bar clamps come in various sizes depending on the width of your project piece.

Pipe Clamp: Pipe clamps are similar to bar clamps in that they also have two jaws connected by a screw mechanism; however, instead of having handles that need to be tightened or loosened with a wrench, pipeclams have threaded pipes running through their center. To adjust the tension on these types of clapsm simply turn the knob at the end of one pipe clockwise or counterclockwise as needed . Pipe crams come in various lengths depending on how long your project piece is .

C – Clamp: C -clamosare heavy duty versions offpipeclams . Like pipe crams ,they alsohavethreadedpipesrunningthroughtheircenter ; however , these pipesaremuchthickerandsturdier , making them ideal foruseonlargerandmorecomplexprojects .Additionally , C – clamos oftencome with built -in ratcheting mechanismsforquickandeasyadjustments .

How Many Clamps Do You Need for a Cutting Board?

You need at least two clamps to secure a cutting board. One clamp should be placed at each end of the board. You may need additional clamps if the board is particularly large or heavy.

What are the Best Quick Release Clamps?

There are a few different types of quick release clamps, and the best one for you will depend on your specific needs. Some quick release clamps have a lever that can be operated with one hand, while others have a knob that must be turned with a wrench. There are also some quick release clamps that can be tightened or loosened with a screwdriver.

The most important thing to consider when choosing a quick release clamp is the size of the jaws. The jaws need to be big enough to grip whatever you’re clamping, but not so large that they get in the way or make it difficult to operate the clamp. You should also make sure that the clamp can generate enough force to hold whatever you’re trying to clamp together.

Another thing to keep in mind is how easy the clamp is to use. If you’re going to be using it frequently, then you’ll want something that’s easy to operate. On the other hand, if you only need it occasionally, then you might be able to get away with something that’s more difficult to use.

Ultimately, it’s up to you to decide what’s most important: ease of use or price?

Credit: thewoodwhisperer.com

Best Clamps for Woodworking

There are many different types of clamps that can be used for woodworking, and the best clamp for your project will depend on the specific requirements of the project. However, there are some general considerations that you should keep in mind when choosing clamps for woodworking.

First, you need to consider the size of the project.

For smaller projects, you may only need a few light-duty clamps. But for larger projects, you’ll need heavier-duty clamps that can apply more pressure.

Second, you need to think about the type of joint you’re trying to create.

Different joints require different types of clamping pressure, so it’s important to choose a clamp that’s appropriate for the joint you’re trying to create.

Third, consider how easy it is to use the clamp. If you’re new to woodworking, then it’s probably best to choose a simple clamp that’s easy to operate.

But if you’re more experienced, then you might want something that gives you more control over the amount of pressure being applied.

fourth , take into account how often you plan on using the clamp . If this is a one – time project , then any type of clamp will do .

But if you plan on using it frequently , then it ‘s worth investing in a higher – quality clamp that will last longer and provide better results .

With these factors in mind , let ‘s take a look at some of the best clamps for woodworking :

1 .

Bar Clamp : A bar clamp is one of the most versatile and commonly used clamps in woodworking . It consists of two jaws connected by a bar , which can be adjusted to apply various amounts of pressure . These clamps are available in different sizes , so they can be used for small or large projects .

2 . C – Clamp : A C – clamp is similar to a bar clamp , but with one major difference : instead of a bar connecting the two jaws , there ‘s a screw thread . This allows for much finer adjustments when applying pressure , making them ideal for delicate work . C – clamps are also available in different sizes depending on your needs .

3 .” F ”

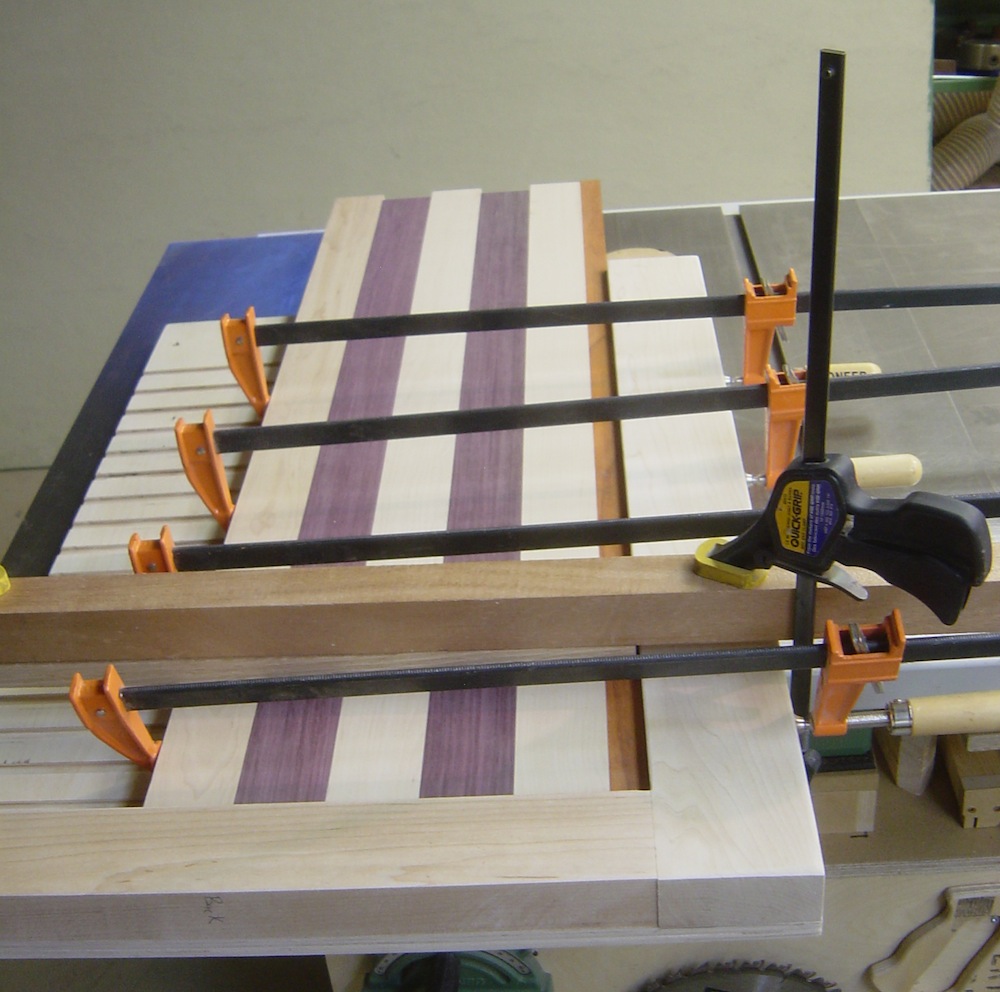

Best Clamps for Glue Ups

When it comes to clamping for glue-ups, you have a lot of options. Which clamps are best for the job? Here is a rundown of some of the most popular types of clamps and their advantages:

Bar Clamps: Bar clamps are one of the most versatile types of clamps, perfect for both small and large projects. They have adjustable jaws that can be opened wide to accommodate different thicknesses, and they can apply pressure evenly across a surface.

Pipe Clamps: Pipe clamps are another great option for glue-ups.

They’re similar to bar clamps, but they have longer jaws that can reach further into corners and tight spaces. Additionally, pipe clamps can be used with threaded rods to create even more clamping power.

C-Clamps: C-clamps are simple but effective.

They have a fixed jaw and an adjustable screw that allows you to apply pressure as needed. C-clamps are great for smaller projects or areas where you need more precision than what bar or pipe clamps can offer.

F-Clamp: F-clamps (sometimes called G-claps) are similar to C-clams but with an added handle that gives you more leverage when tightening them down.

This makes them ideal for larger projects where you need lots of clamping power.

Parallel Clamps

If you’re working with wood, you need a good set of clamps to help hold everything together while you work. And if you’re working on a big project, you’re going to need a lot of clamps. That’s where parallel clamps come in.

These clamps are designed to be used in pairs, and they provide a ton of holding power for even the biggest projects.

Here’s how they work: each clamp has two jaws that open and close independently. When you open both jaws at the same time, they move apart from each other in a perfectly parallel fashion.

This gives you a ton of surface area to work with, which is ideal for gluing or clamping large pieces of wood together. Plus, the fact that the jaws move independently means that you can adjust each one individually to get just the right amount of pressure on your project.

Parallel clamps are an essential tool for anyone who works with wood on a regular basis.

If you’re looking for maximum holding power and flexibility, they’re the way to go.

Bessey Clamps

Bessey Clamps are a great way to get a grip on your woodworking projects. There are many different types and sizes of clamps, so you can find the perfect one for your needs. Bessey clamps are made from high-quality materials, so you can trust that they will hold up to heavy use.

And if you ever have any questions about using or caring for your clamps, the friendly staff at Bessey is always happy to help.

Pipe Clamps

If you’re working on a plumbing project, you may need to use a pipe clamp. Pipe clamps are devices that secure pipes in place so that they can be worked on. There are many different types of pipe clamps available, and each has its own advantages and disadvantages.

Here’s a look at some of the most popular types of pipe clamps:

1. spring-loaded pipe clamps: These clamps have a spring-loaded mechanism that makes them easy to open and close. They’re ideal for quick, temporary fixes.

However, they’re not as strong as other types of clamps, so they’re not suitable for permanent applications.

2. screw-type pipe clamps: These clamps have a screw that tightens or loosens the clamp’s grip on thepipe . They’re easy to adjust and provide good holding power.

However, they can be difficult to remove once they’re tightened down.

3.”C” clamp: This type of clamp is similar to a screw-type clamp, but it has an added “C” shaped piece that helps distribute the holding force evenly around the circumference of the pipe . This makes “C” clamps ideal for larger diameter pipes .

4.”G” clamp: A “G” clamp is similar to a “C” clamp, but it has two screws instead of one . This allows you to adjust the tension on each side of thepipe independently , which is helpful when working with oddly shaped pipes .

5.”Saddle” style pipe clip: A saddle style clip holds the pipe in place by straddling it like a saddle would sit on a horse .

These clips are often used in pairs , with one on either side of thepipe . They provide good stability and are easy to install and remove.

Best Spring Clamps

As the weather gets warmer, it’s time to start thinking about all of the fun projects you can do outdoors. One of the best things about spring is that there are so many ways to spruce up your home and yard. If you’re looking for a way to add a little bit of personality to your space, consider using colorful clamps to hold down your fabric in place.

Here are some of the best spring clamps to use for all of your outdoor projects:

1. Alligator Clips: These are great for holding down lightweight fabric or paper. They come in a variety of colors and sizes, so you can find the perfect ones for your project.

2. Bulldog Clips: These clips are sturdier than alligator clips, making them ideal for heavier fabrics. They also have a non-slip grip, which keeps them in place better.

3. Spring Clamps: These are versatile clamps that can be used for a variety of projects.

They have strong jaws that open wide, making them perfect for holding down fabric or paper securely.

4 . Magnetic Clips: These clips are perfect for holding photos or other light materials in place on a fridge or other metal surface.

Bar Clamps

A bar clamp is a simple yet versatile tool that can be used for a variety of tasks in the woodshop. from clamping boards together during gluing and assembly to holding workpieces in place while you drill or rout them, bar clamps are an essential part of any woodworker’s arsenal.

There are two basic types of bar clamps: those with fixed jaws and those with sliding jaws.

Fixed jaw clamps have their jaws permanently attached to the bar, while sliding jaw clamps have jaws that slide along the length of the bar, allowing you to adjust the width of the clamp to fit your workpiece.

Most bar clamps have wooden handles, but some models have metal handles that can be adjusted to different positions depending on your needs. Some also have padded jaws to protect your workpiece from damage.

When choosing a bar clamp, consider the size and weight of your workpieces as well as how much force you’ll need to apply to get a tight grip. Also think about whether you need a fixed or sliding jaw clamp and whether adjustable handles would be helpful. With so many options available, there’s sure to be a perfect bar clamp for your next project!

Conclusion

If you’re looking for the best clamps for cutting boards, you’ve come to the right place. In this blog post, we’ll discuss the different types of clamps available and which ones are best suited for cutting boards. We’ll also provide a few tips on how to use these clamps effectively.